INNOVATIONS

DELIVERING THE DREAM of flight

iFLY invented modern indoor skydiving; we created the technology and pioneered the system that allows anyone to enjoy flying safely all over the world. For over 20 years, we have set industry standards and driven innovation to make the dream of flight thrilling but safe, comfortable, accessible, and economical.

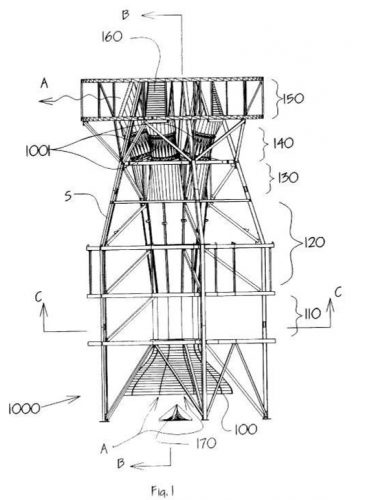

WALL-TO-WALL AIRFLOW

People had flown in wind tunnels, but originally, it was unsafe to non-skydivers. The key innovation was wall-to-wall airflow. This invention alone eliminated the potential for a flyer to fall off of the air stream and in doing so, made it safe for people of all ages and physical abilities to fly. It opened up indoor skydiving to the first-time flyer market.

Staging Area

and Cable floor

Additional key safety innovations of our first wind tunnel include the staging area and cable floor.

The Staging Area prevents unauthorized access to the Flight Chamber and blocks the transmission of sound from the wind tunnel to the viewing area.

The Cable Floor safety net at the bottom of the Flight Chamber was also invented keeping flyers safe and allowing instructors to stand right beside them as they learned.

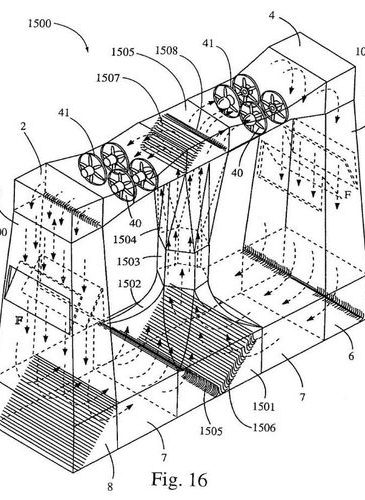

THE RECIRCULATING WIND TUNNEL AND FAN LOCATION

We created and patented the first modern recirculating wind tunnel for indoor skydiving in 2005. This innovation dramatically improved the energy efficiency of the wind tunnel, improved the consistency of the airflow and provided a repeatable experience regardless of the external weather conditions. With this arrangement we located the fans in the top leg of the wind tunnel which enables the maximum downstream distance between the flyers and the fans for optimal safety and flow quality as well as ease of access for maintenance.

mULTI-STAGE

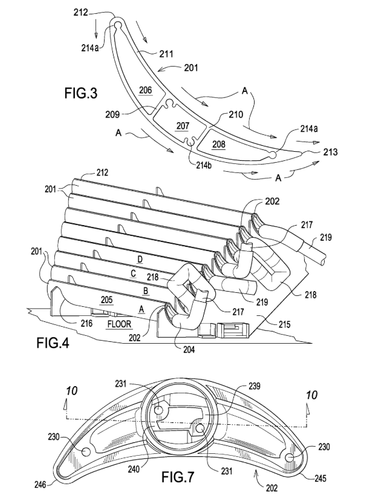

INLET CONTRACTOR

A follow-on invention was the creation of a two stage Inlet Contractor whereby the flow is reduced before the final turn of the airflow. This technique reduces the overall height of the wind tunnel, resulting in cost savings and enabling us to minimize the excavation required in construction.

TURNING VANE

HEAT EXCHANGER

Wind tunnels produce heat, and a lot of it. All of the power put into a recirculating wind tunnel eventually turns into heat due to friction of air molecules. The original recirculating wind tunnel invention exhausted this heat through large air exchange louvers to passively cool the air. Louvers however, lead to large energy losses and cause minor increases in flow turbulence. With such passive cooling, it’s never possible to cool the airflow beneath the ambient outside temperature.

For one of our most impactful inventions, we created a way to convert a turn assembly into an air-to-water heat exchanger in a cost-efficient manner. This allows cold water to be pumped through ‘turning vanes’ that in turn cools the passing air to a temperature of our choice. This active cooling system uses typical commercial building chillers.

CONtinuous INNOVATION

Our engineers continue to innovate, to supply you better wind tunnel designs with a lower build cost, faster construction time, and higher quality.